Solutions

E2i’s interactive tool welcomes you into the virtual world of manufacturing automation, by way of a water-bottling plant.

Through our animated environment we share an in-depth look into the services we provide and the benefits of a systems integrator. For a manufacturing 101 synopsis scroll down the page.

Maintaining Consistency in Product-Making

A well-constructed process reduces numerous factors that can degrade efficacy. Many plants today still use manually-operated machinery, due in part to the misconception that the cost is something they cannot afford. Computerized precision allows you to output products with unparalleled consistency—even with minimal supervision—and ensures accuracy and reproducible outcomes. We’ll be happy to show you why it’s too expensive not to upgrade your system and to provide you with “the HOW,” to stay ahead of your competition.

Increased Productivity

E2i’s automation, validation and intelligence solutions are developed to be perpetually reliable. Specialized equipment, sensors, and streaming data must be compiled and designed to function harmoniously, in/on a diversely-integrated network. Reducing a factory’s cycle times not only increases productivity, but also its cost savings and uptime. Let us show you how our meaning of “downtime” is vastly different from yours. As we build-in streamlined process controls, you can relax knowing that E2i has your back every step of the way.

Regulating Process Using Big Data Intelligence

In a setting as complex as a plant or global supply chain, a process automation system (PAS) can monitor a multitude of performance values and output quality. The data that’s derived and processed from your Historian allows continued system refinement. Turn-key modifications are only possible when software and hardware have the ability to leverage the intelligence that analysis and transformation of data can provide: greatly improving the efficiency and ROI of any manufacturing site.

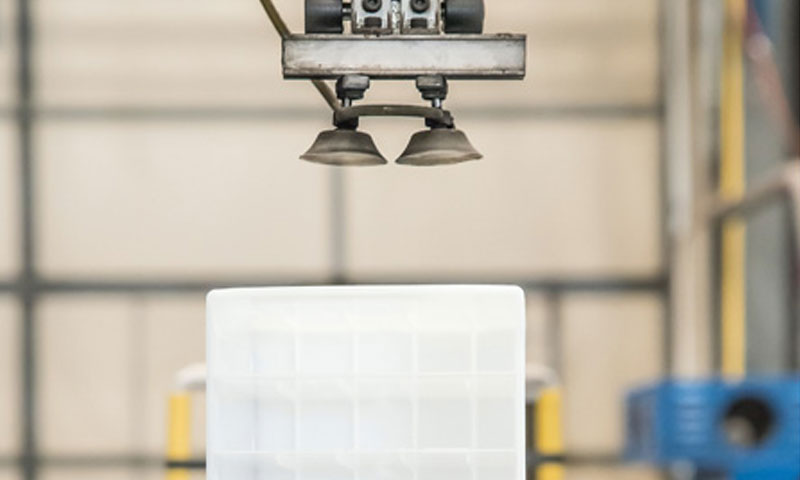

Speed And Consistency Breeds Safety And Reliability

Fully-automated environments equal repeatable precision and speed, offsetting the hazards your staff could face in a manufacturing and assembly environment. Leaving hazardous tasks to machinery keeps employees out of harm’s way, but so does ensuring that commissioning and qualification happens along the full spectrum. E2i’s recipe for success also includes network debugging for distributed I/O, monitoring capabilities from one controller, critically-placed RFID technology, and software and equipment virtualization made possible using our customizable simulators.