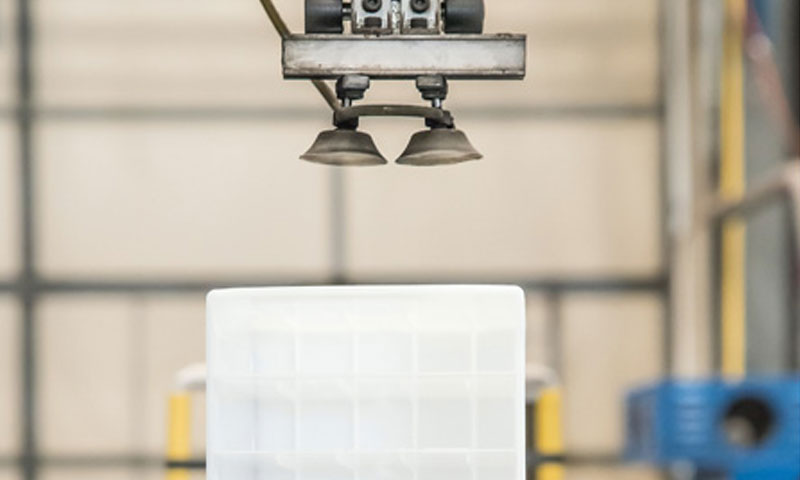

CIP Tanks & Freeze Dryers

PROJECT DESCRIPTION

E2i served as the automation and testing resource to automate the CIP systems used for cleaning portable tanks and freezer dryers in a pharmaceutical formulation and filling facility that was being repurposed for new products. In addition to piping and instrumentation changes to the CIP system, both the PLC and HMI required extensive modifications to support the new process and the addition of recipe downloading. This project included two CIP systems which utilized common purified water and water for injection feed tanks and shared acid/base storage and delivery system. E2i developed all the automation documentation for the project including requirements and design documents.

In addition to the software services, E2i provided the testing resources to fully qualify the systems. This included writing and executing all the automation test cases in both qualified offline environments and on the production equipment in the manufacturing building.

Operator support was provided including the development of standard operating procedures and training. E2i also created custom batch reports for the CIP cycles utilizing historical data collected by the data historian system.

SOFTWARE/SYSTEMS

- Allen-Bradley ControlLogix Controller, v13.44

- Allen-Bradley Factory Talk View SE, v7.00