Filter Press Optimization

PROJECT DESCRIPTION

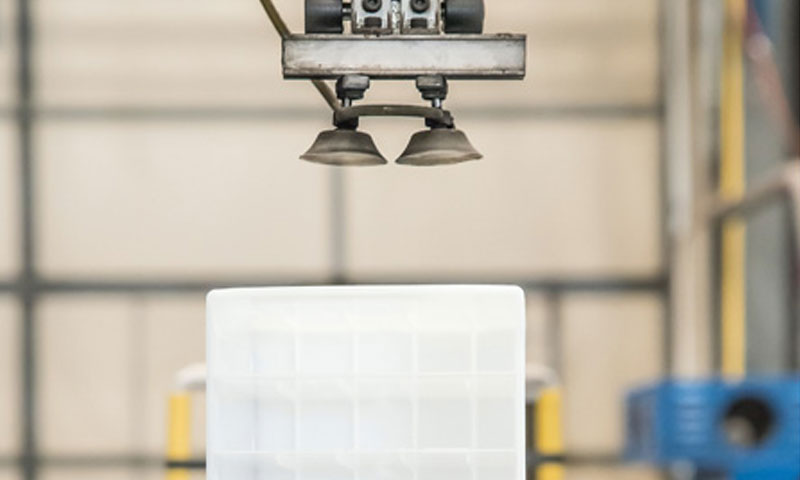

A customer expressed a need for process improvements on their filter press cleaning operation. The COP operation was identified as a bottleneck in their process that was critical to their ability to meet capacity projections. The process consisted of an overhead gantry and two washing chambers. The gantry was used to locate the filter plates and transport them to the correct washing chamber where they are rinsed off to remove any remaining filtration residue. Once washed, the gantry transports the washed plates back to the press. After all plates were washed, a CIP operation would be completed before the press was ready for the next filtration.

Using Studio 5000 and FactoryTalk View SE, E2i made programming and HMI updates to improve the speed and reliability of the equipment as well as improve the usability of the system to reduce downtime. E2i used their extensive background in process knowledge to find the best way to reduce plate transport times as well as plate washing durations. The cycle time reductions were accomplished with optimized motion parameters and improved washing pressure control.

These measures resulted in improved cycle times from 90 minutes to 75 minutes for the larger filtration package and 60 minutes to 45 minutes for the smaller filtration package. The faster turnaround times between filtrations enabled the client to achieve batch times beyond their initial capacity expectations.

SOFTWARE/SYSTEMS

- Software

- Studio 5000 v30

- FactoryTalk® View SE v8.1

- Hardware

- ControlLogix L73

- Kinetix 5500 Servos

- PowerFlex 70 VFD