Transforming Production Through Automation

A CASE STUDY ON BUILDING A WORLD CLASS PLASMA FRACTIONATION FACILITY

Manufacturers pursue solutions to increase production efficiency while decreasing production time. The solution lies in production upgrades which need to be performed quickly and inexpensively while avoiding costly implementation missteps. Improvements in digital technology can deliver the cost saving upgrades in increasingly shorter timeframes while reducing many errors that slow or stop implementation in its tracks.

Innovative usage of 3D, or digital twin, modeling during the planning phase ensures that every facet of production can be built, programmed and monitored under real-time operational conditions. Digital modeling produces cost savings by reducing validation and qualification run times as well as by employing a vigorous and reliable controls system where operations management and data analytics are brought under one efficient and adaptable system. Optimizing automation in the pharmaceutical industry increases workflow, data integrity, and system monitoring.

The following paper is a case study of an E2i project discussing the automation of a blood plasma fractionation process and the significant improvements in production results meant minimizing production times, operator error, product loss, and deviant events for a pharmaceutical client.

Our engineers successfully confronted production issues involving product flow; pressure, time and temperature monitoring; product consistency; and instrumentation maintenance and operator reliability.

Let’s dive in.

Background

The client’s upgraded plasma fractionation facility was installed in a newly constructed, four story-tall, 321,000 square foot building. Equipment totaled 160,000 square feet while the remaining space was reserved for a second project expansion. Piping of 160,000 linear feet was also installed.

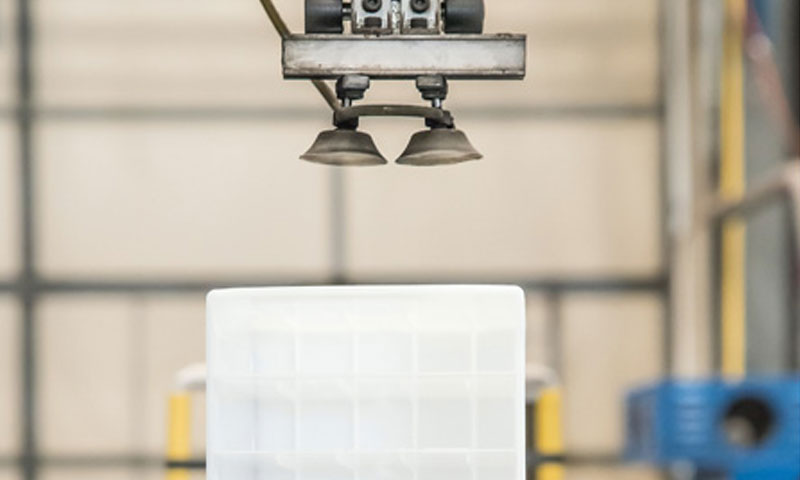

The client facility employs an automated batch control system. E2i managed the performance execution of all equipment including process vessels, centrifuges, ultrafiltration skids, equipment washers, filter presses, Clean-In-Place (CIP) skids, chromatography skids, pasteurizers, and extensive piping and valving for all product and CIP flow paths. Plasma fractionation is the process of extricating plasma into its component proteins. The first step in fractionation is the 3-part pooling process: thawing, centrifuging and collecting the resulting supernatant.

From the pooling phase, the product is moved through four identical fractionation bays which can be operated in parallel. A combination of suspensions, buffers, water and alcohol are added to the plasma at different points in the process, enabling the extraction of specific proteins. The resulting product (suspension) is then sent through a filter press where it becomes a solid. The final step is liquification and purification when the solid protein is added to water in a mixing tank before being bottled. This process is materially supported by other tanks, skids, and piping used to transport buffers, water and alcohol for fractionation as well as preparation and flushing washes for filtration and equipment cleaning.

Challenges

The manual plasma fractionation system, though functional, cannot operate at the level of a highly automated system. The former leaves many process decisions to operators who may not consistently perform duties as expected. Small errors in judgment can impact the outcome of an entire batch.

One issue that plagues plasma processing is temperature. Maintaining proper temperature ensures safe and reliable plasma processing. An increase of even a few degrees can be cause for batch disposal. The initial thawing of plasma is a step where product loss can occur when the temperature is not monitored properly before moving plasma to the centrifuge tanks.

The use of manual valves can also be a pain point in plasma processing. Controlled by buttons pressed by operators, valves are used for temperature control by introducing pure glycol into the system and for moving product from one step to the next.

Equipment cleaning presents challenges as well. In the final filtration stage, plasma is strained through large filter plates where it remains until it forms a solid. The solid protein is scraped from the plates for further processing leaving behind some residue. Operators then manually scrub the plates clean with large brushes and a cleaning solution. This work is performed in a cold room with wet floors, creating an injury risk from slipping and falling.

In non-automated systems, data collection is completed by written reports. The accuracy of these reports depends on operators’ abilities and memory. In addition, trying to collect information for reports across all areas of processing for management can be a complicated and time-consuming endeavor. For each step in processing, an operator’s failure to follow correct procedure could result in serious processing issues.

Solutions

Solutions were achieved during the development stage of the automation upgrade using

the 3D digital twin. A digital twin is a virtual model of a physical process. It is programmed

to assess production conditions, access all historical processing data, and simulate future

production activities based on its ability to analyze that data.

By building a simulated environment, stakeholders can monitor systems, analyze data, and

predict potential problems in a non-simulated environment. A digital model helps

engineers examine current production tasks, production times, and production yields. The

production model can be virtually run many times until expected capacity goals can be

met.

A digital simulation enables programmers to determine where and how to capture the

most useful data for detecting performance deviations. Capturing this data allows

stakeholders to predict critical quality attributes and anomalies for all process operations.

Gathered over time, this data is used to develop robust and strategic risk assessments

based on dozens of simulated runs.

These run batches can provide data driven testing modules which allow stakeholders to

reduce the amount of time needed for validation qualification. They can also confirm

production parameters necessary for validation and show that every part operated by the

controls system meets production times.

In the plasma processing system, a digital twin model was used to examine each step in the

fractionation process, establishing theoretical high-yield production capacity within an

incident-free production. Process times for product addition, transfer, filtration and

equipment cleaning were established for all equipment.

By monitoring each step in the process, engineers can solve challenging issues before

validation or production implementation. Engineers extracted data from temperature

sensors and tank loading speed sensors to create a custom temperature control algorithm.

This data helped engineers to conclude that optimal temperature control could be

achieved by determining maximum temperature and time setpoints for plasma to thaw.

The developed process entailed increasing tank temperature while the product is loading

and lowering the temperature during the thaw to ensure the product retains full

processing attributes. Once the product reaches the predetermined setpoints, a signal

notifies the operator to advance product to the next step. By establishing temperature

setpoints, the rate of plasma thaw is predictively controlled.

In an automated process, flowmeters gauge the volume of product as it passes. Once the

volume of product passing a flowmeter reaches the preset value, a signal is sent to a valve

to close. The automated programming ensures consistency in final batch yields because

the sensor is programmed to perform in the consistent manner based on product volume

setpoints.

Automated cleaning improved three areas of concern: residual product removal,

consistency in absolute cleaning, and operator safety. Solid product is removed manually

by operators. When the plates are cleaned, any remaining product residue is removed and

sent for further processing instead of being discarded. A validated cleaning procedure

ensures that plates are cleaned consistently and thoroughly every time, something that

was not possible to do with a manual cleaning. Thirdly, operator safety was improved as

they were no longer required to be in the room with wet, cold, slippery conditions.

An automated reporting system delivers accurate and time-saving attributes while

providing transparency of both detailed and overall system performance. Operators

and managers have real-time access to precise production data by means of a specified

reporting system without having to weed through all the available data in the system.

Operators can see processing anomalies in these generated reports, refer to historical data

to pinpoint where errors occur and quickly respond to solve issues.

A Rockwell alarm and events database and a separate Werum MES database can be

integrated into a plant-wide historian. Information can be drawn from the plant historian,

MES and alarm and events server to create comprehensive reports. The information

garnered from these databases can be scaled based on the needs of the facility.

Stakeholders can access real-time data, quality control data and operational metrics

ensuring that the information from the plant floor is delivered to the people who need it to

make the best decisions.

The alarm and events server provide informational and system reports from the HMI. In

addition to being able to pull historical and current information, reports can be pulled for

quality, auditing or Corrective and Preventative Actions (CAPA) to be examined for system

monitoring and correction.

By creating and executing a reliable simulated environment, system evaluation for

production deviations and their root causes are easier to make, leading to faster solutions

and decreasing system downtime.

Results

The automated process was able to achieve substantial improvements in production.

Engineers were able to work with R&D to determine guidelines for increasing product

throughput while maintaining quality control and reducing processing times:

• The initial filtration process decreased to 30 minutes from a 50-minute manual

processing time.

• The final filtration now averages 90 minutes, reduced from an approximately 2 to 2.5-

hour manual process.

• Initial guidelines for the COP/CIP process was < 90 minutes. The recipes written

were able to achieve operational times of 75 minutes for larger batches and 60

minutes for smaller batches.

• Automation brought equipment utilization down to 90% from 100%. Additional

equipment implementation in future upgrades will decrease overall equipment

usage even further.

Using a digital twin to simulate production design programming and execution allows for

more meticulous management of process time reduction and resource allocation.

The value of digital modeling is in its ability to provide real-world assessments from design

and development to end of product life cycle. It enables users to solve physical process

issues faster and utilize algorithms for real-time feedback and analysis, further accelerating

change in design and processing. The end results in physical production are improved

equipment performance, reduction in product inconsistencies, and the ability to unlock

previously unidentified process issues.