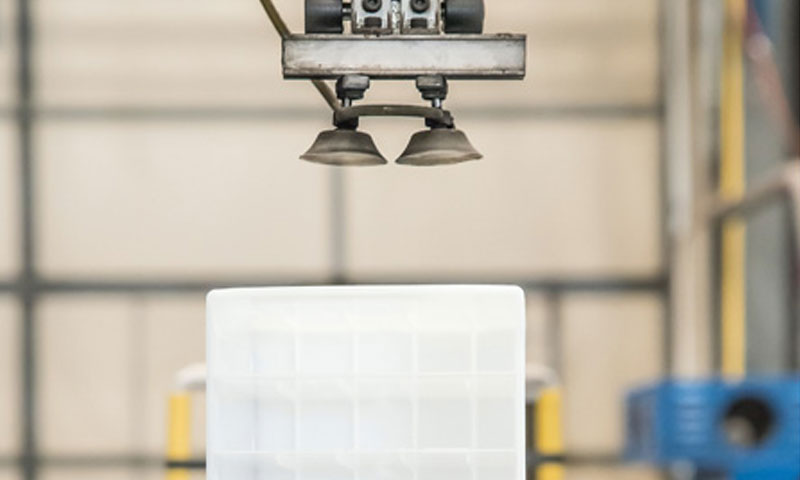

Empowering Manufacturers with Actionable Data Insights

In today’s digitized manufacturing landscape, data flows abundantly from every corner of the factory floor, presenting both a wealth of opportunity and a significant challenge for industrial manufacturers in learning from these data insights.

At E2i, we recognize the power of data and strive to unlock its full potential to drive informed decision-making and operational excellence.

The Upsurge of Data: A Treasure Trove Waiting to be Unveiled

From advanced transmitters delivering multivariate data to the vast reservoir of time-series data stored within process historians, the modern manufacturing environment generates an avalanche of data points every second. However, the real challenge lies not in the abundance of data, but in its effective analysis and utilization.

Unlocking the Potential: Transforming Raw Data into Actionable Insights

One of the critical hurdles in manufacturing operations management is the transformation of raw data into actionable insights in real-time. At E2i, we understand the importance of contextualizing data to make it truly actionable. By integrating crucial information such as product specifications, recipes, and operator details with time-series data, we create a comprehensive framework for analysis and decision-making.

Tailored Insights for Every Department

Different departments within a manufacturing facility have unique priorities and requirements when it comes to data analysis. Our approach at E2i is to provide contextualized data insights tailored to the specific needs of each department. Whether it’s downtime root cause analysis for maintenance or production schedule adherence for the operations team, we ensure that every stakeholder receives the insights they need to drive efficiency and productivity.

The Crucial Role of Contextual Data: Enhancing Operational Performance

Contextual data isn’t just about understanding the past; it’s about shaping the future of manufacturing. By leveraging contextual data, manufacturers can enhance overall equipment effectiveness (OEE), streamline production processes, and identify opportunities for improvement. Automated data collection further ensures accuracy and consistency, laying the foundation for data-driven decision-making.

Embracing Big Data: Unlocking New Frontiers in Manufacturing

With the rise of big data analytics, manufacturers have unprecedented opportunities to gain real-time visibility into their operations and drive continuous improvement. From predictive maintenance models to cloud-based digital twins, the possibilities are limitless. At E2i, we are committed to harnessing the power of big data to propel our clients towards greater efficiency and competitiveness.

Join Us on the Journey to Data-Driven Excellence

At E2i, we believe that data is not just a commodity—it’s a catalyst for innovation and growth. Contact us today to learn more about our manufacturing operations management capabilities and discover how we can help you unlock the full potential of your data.