Validation

Meeting Quality Standards Is Top Priority at E2i

We are a systems integrator who’s end goal is to improve functional efficiency and increased quality standards that uphold current legislation and compliance to provide our clients “a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specification and quality attributes.” We apply computer system validation to ensure that the manufacturing process produces consistent, documented evidence that verifications and testing have been met.

Commissioning & Qualification

E2i’s comprehensive commissioning and qualification assurance services include documentation, testing and execution of code against test cases to mitigate risk and implement necessary modifications for process start-ups, or retrofits.

At E2i we mitigate validation issues by having our hand in multiple aspects of a project, not just the programming!

E2i is composed of pharmaceutical and healthcare systems specialists, which makes us a valuable validation partner in the handling of GMP/GLP/ISO projects, including manufacturing, packing, and distribution processes. We ensure that your production, warehouse system, and logistics process complies with regulation using a risk-based approach to validate and analyze critical points.

E2i Simulator Projects

As a systems integrator, E2i has had significant project history with sustainable, data-rich validation methods. Our team of engineers, through using the industry’s top plant-optimization protocols, is able to effectively manage our clients’ processes.

Zero Downtime – Part-Fill Line Phase I & Phase II

As part of a control system package, E2i provided an RSTestStand simulation for two part-fill machines and one surge tank.

- The Client was able to interact with the virtual machine before the physical machine was built, allowing for machine updates and programming optimization during the design phase of the project

- As production personnel requested updates to the original design, these requests could be demonstrated offline before applying the changes to 10 machines

- Each of the validation protocols were dry-run offline. All discrepancies were communicated and resoled before the plant shutdown

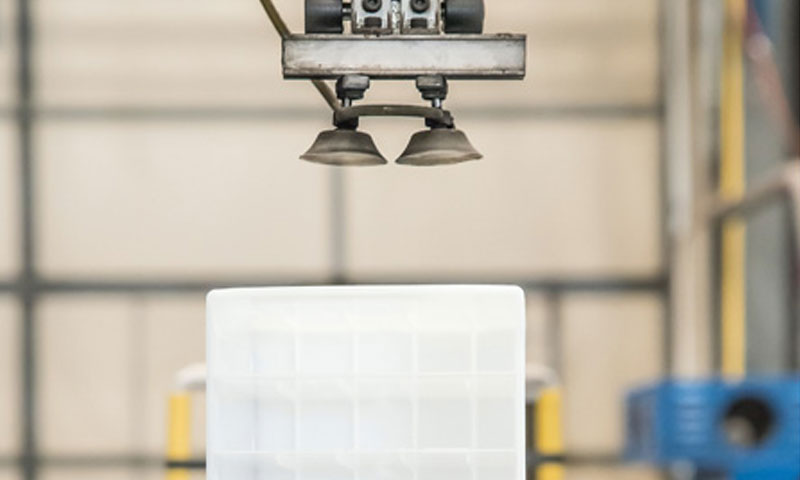

80% Savings – High-Speed Plastic Forming Machines

As part of internal testing and design, E2i created a RSTestStand simulation for a high speed plastic forming machine.

- E2i interacted with the virtual machine before the physical machine was built, allowing for machine updates and programming optimization during the design phase of the project

- Client scheduled 60 hours for start-up and debug of the system; E2i completed these tasks in 12 hours – resulting in 80% savings

- During Phase II, two new surge tanks and eight new part-fill machines were added to the production floor

- Each program was tested against the simulation environment during FAT

25% Savings – WFI Production and Distribution

As part of a control system package, E2i programmed process simulation modules within the ladder logic.

- Three HMIs and Four PLCs were programmed and tested offline.

- Commissioning and Qualification was completed with no discrepancies, or exceptions, allowing the system to be RTO’d (need translated) a day and a half ahead of schedule resulting in a 25% savings

- E2i was able to test and debug HMI screens and PLC programming enabling the client to save two days on installation and startup testing

- This simulation environment streamline the machine sequence prior to even being on the production floor